|

|

Clutches |

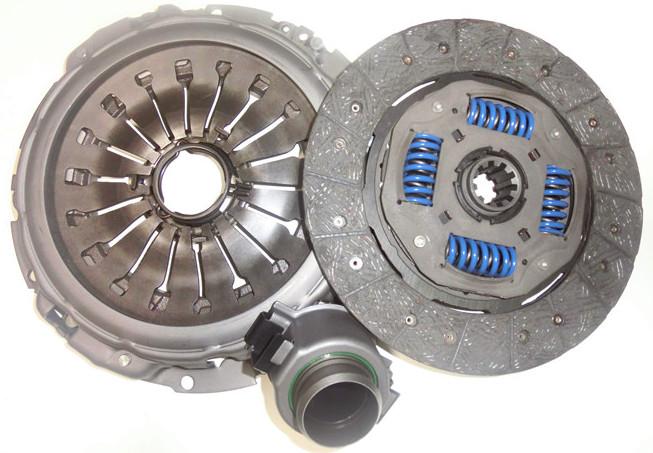

Knatmoto Clutches

OE Replacement Clutch Kits

Quality

The centerpiece of the KNAT Clutch Products Program is its OE Replacement Clutch Kits. No other clutch kit supplier can offer components that exceed the OE quality that KNAT offers. Many program repackagers do not offer high percentages of OE specified clutch covers and discs. You can expect long life and smooth engagement from KNAT’s clutches because of our focus on quality.

Value

KNAT’s kits contain every component that a technician needs to change out a clutch. Each kit contains a clutch disc assembly, pressure plate cover assembly, release bearing, alignment tool, grease pack, and installation guide. Also included when necessary are a pilot bearing, and technical service bulletin. Some kits also come with a flywheel. KNAT’s numeric, user-friendly part numbers have been designed to support the marketplace.

Packaging

KNAT’s clutch kits use packaging that is state of the art to ensure that the product arrives and remains free of damage right up to the time it is installed in a vehicle. The extra durable locking tabs ensure product security within its packaging until it is removed for final installation. Our kits are packaged in an attractive, reinforced box that includes hand held slots for the heavier kits. Other features of the packaging include: re-sealable foam insert for enhanced box and component protection, and a smart label where the part number is coded for size and vehicle make, shown vertically and horizontally with competitor interchanges. KNAT’s clutch kits use packaging that is state of the art to ensure that the product arrives and remains free of damage right up to the time it is installed in a vehicle. The extra durable locking tabs ensure product security within its packaging until it is removed for final installation. Our kits are packaged in an attractive, reinforced box that includes hand held slots for the heavier kits. Other features of the packaging include: re-sealable foam insert for enhanced box and component protection, and a smart label where the part number is coded for size and vehicle make, shown vertically and horizontally with competitor interchanges.

Exceptional Coverage

KNAT offers new clutch kits for over 30,000 vehicle applications in North America. KNAT is the quality clutch supplier worldwide to the Original Equipment Manufacturers. KNAT is also the world leader on clutch disc facings. Our kit range covers over 50 model years and about 50 vehicle makes from domestic to import. KNAT clutch kits are OE Engineered…Aftermarket Delivered!

Performance Clutch Kits

The KNAT Signature Series is designed for drivers who demand higher than stock performance from their clutch without having to pay a premium price for it.

Key Features:

- Up to 15% increase in holding capacity

- Performance friction material with a high burst strength

- Increased heat resistance and recoverability

- Excellent friction and wear performance

if you need more Clutch Kits product, please e-mail get Clutches Catalogue.

contact us e-mail: info@knatmoto.com

we will give you reply within 24 hours.

Knatmoto Company Professional to solve your clutch problem.

CSC Clutch Kits = Flywheel + Cover + Disc + Bearing.

Clutch Parts failure and the suggestion/solution as below:

Failure on flywheel

1.1 Born marks on the flywheel

Cause

• Excessive greasing of the spline hub when installed.

Suggestion

• Clean the flywheel and replace the clutch disc.

Solution

• Apply the correct amount of grease on the clutch disc splines and the input shaft.

Cause

• Excessive greasing of the spline hub when installed.

Suggestion

• Clean the flywheel and replace the clutch disc.

Solution

• Apply the correct amount of grease on the clutch disc splines and the input shaft.

____________________________________________

Failure on cover

2.1 Noise while depressing clutch pedal

Cause

• Off centering of the release bearing or mis-alignment of the main shaft.

Suggestion

• Replace the release bearing.

• Realign the engine and the gear box.

2.2 Burn marks on the pressure plate

Cause

• Off centering of the release bearing or mis-alignment of the main shaft.

Suggestion

• Replace the release bearing.

• Realign the engine and the gear box.

2.2 Burn marks on the pressure plate

Cause

• Oil or grease contamination on the clutch linings or on the pressure plate.

Suggestion

• Locate and repair all sources of contamination.

• Replace the clutch kit.

Solution

• Apply the correct quantity of grease on the clutch disc splines and the input shaft.

• Do not use contaminated pair of gloves.

2.3 Circular grooves appearing on the pressure plate

Cause

• Oil or grease contamination on the clutch linings or on the pressure plate.

Suggestion

• Locate and repair all sources of contamination.

• Replace the clutch kit.

Solution

• Apply the correct quantity of grease on the clutch disc splines and the input shaft.

• Do not use contaminated pair of gloves.

2.3 Circular grooves appearing on the pressure plate

Cause

• Linings worn out, heads of the facing rivets are in contact with the pressure plate.

2.4 Finger worn asymmetrically

Cause

• Linings worn out, heads of the facing rivets are in contact with the pressure plate.

2.4 Finger worn asymmetrically

Symptom

• Shudder when start the car, difficult disengagement, noisy changing gear.

Cause

• Diaphragm spring was amounted asymmetrically

• Release bearing was not concentric.

• The main shaft was lead.

Solution

• Change a new cover.

2.5 The finger of clutch cover interfering with clutch disc

Symptom

• Shudder when start the car, difficult disengagement, noisy changing gear.

Cause

• Diaphragm spring was amounted asymmetrically

• Release bearing was not concentric.

• The main shaft was lead.

Solution

• Change a new cover.

2.5 The finger of clutch cover interfering with clutch disc

Cause

• The release bearing is over stroke which causes interfere.

• The clutch cover is incorrect.

• The clutch disc is incorrect.

• The size of clutch disc is out of tolerance.

• Not all the clutch with same dimension and amounting size could be used.

Suggestion

• Change a new clutch kit completely.

Cause

• The release bearing is over stroke which causes interfere.

• The clutch cover is incorrect.

• The clutch disc is incorrect.

• The size of clutch disc is out of tolerance.

• Not all the clutch with same dimension and amounting size could be used.

Suggestion

• Change a new clutch kit completely.

____________________________________________

Failure on disc

3.1 Cushion plate broken

Cause

• The disc has been distorted when refitting the gear box on the engine.

• The engine and the gear box are misaligned.

• The pilot bearing is damaged.

• Aggressive driving.

Suggestion

• Replace the clutch kit.

• Realign the engine and the gearbox.

• Replace the pilot bearing.

Solution

• Be careful in selecting the gears and do not over run the clutch.

3.2 Clutch disc plate broken

Cause

• The disc has been distorted when refitting the gear box on the engine.

• The engine and the gear box are misaligned.

• The pilot bearing is damaged.

• Aggressive driving.

Suggestion

• Replace the clutch kit.

• Realign the engine and the gearbox.

• Replace the pilot bearing.

Solution

• Be careful in selecting the gears and do not over run the clutch.

3.2 Clutch disc plate broken

Cause

• Defective clutch installed or wrong direction for installation.

Suggestion

• Make sure that the correct kit is used on the application.

3.3 Clutch lining damaged

Cause

• Defective clutch installed or wrong direction for installation.

Suggestion

• Make sure that the correct kit is used on the application.

3.3 Clutch lining damaged

Cause

• Excessive slippage due to aggressive driving or overloading.

• The clutch operating system is badly adjusted or defective.

Solution

• Replace the clutch kit.

• Replace or machine evenly the flywheel.

3.4 Damper spring break away

Cause

• Excessive slippage due to aggressive driving or overloading.

• The clutch operating system is badly adjusted or defective.

Solution

• Replace the clutch kit.

• Replace or machine evenly the flywheel.

3.4 Damper spring break away

Cause

• Wrong clutch cover size used.

• Excessive release travel.

• The clutch disc is installed on the wrong side.

Suggestion

• Replace the flywheel.

• Adjust the clutch operating system, (pedal height, self adjusting system, clutch linkage...)

• Install the clutch disc properly.

Solution

• Make sure that the correct kit is used on the application.

3.5 Deformation of the clutch disc

Cause

• Wrong clutch cover size used.

• Excessive release travel.

• The clutch disc is installed on the wrong side.

Suggestion

• Replace the flywheel.

• Adjust the clutch operating system, (pedal height, self adjusting system, clutch linkage...)

• Install the clutch disc properly.

Solution

• Make sure that the correct kit is used on the application.

3.5 Deformation of the clutch disc

Cause

• Deformed during delivery or handling.

• Deformed during installation,(weight of the gear box, dropped)

• Deformation due to overheating during slippage.

Suggestion

• Handle with care.

• Do not place the clutch disc under a weight.

3.6 Clutch facing completely worn

Cause

• Deformed during delivery or handling.

• Deformed during installation,(weight of the gear box, dropped)

• Deformation due to overheating during slippage.

Suggestion

• Handle with care.

• Do not place the clutch disc under a weight.

3.6 Clutch facing completely worn

Cause

• Use over product lifetime.

• Prolonged clutch slippage due to a malfunction or extremely severe use.

Disc not changed during a previous flywheel I cover replacement.

3.7 Clutch lining contaminated with oil or grease

Cause

• Use over product lifetime.

• Prolonged clutch slippage due to a malfunction or extremely severe use.

Disc not changed during a previous flywheel I cover replacement.

3.7 Clutch lining contaminated with oil or grease

Cause

• Excessive greasing of the spline hub when installed.

• Oil leakage from engine or gear box.

Suggestion

• Replace the clutch disc.

• Locate and repair all sources of contamination.

Solution

• Apply the correct amount of grease on the clutch disc splines and the input shaft.

3.8 Over torque

Cause

• Excessive greasing of the spline hub when installed.

• Oil leakage from engine or gear box.

Suggestion

• Replace the clutch disc.

• Locate and repair all sources of contamination.

Solution

• Apply the correct amount of grease on the clutch disc splines and the input shaft.

3.8 Over torque

Cause

• Excessive engine brake operation.

• Incorrect disc for the application.

• Aggressive starting operation.

• The clutch operating system is badly adjusted or defective, (clutch pedal).

Suggestion

• Replace the clutch disc.

3.9 Noise when in neutral

Cause

• Excessive engine brake operation.

• Incorrect disc for the application.

• Aggressive starting operation.

• The clutch operating system is badly adjusted or defective, (clutch pedal).

Suggestion

• Replace the clutch disc.

3.9 Noise when in neutral

Cause

• Lack of care during installation, splines have been damaged by the gear box main shaft.

Suggestion

• Replace the main shaft.

• Replace the clutch disc.

Solution

• Make sure that the splines properly match up.

• Lubricate with a proper quantity of grease.

Cause

• Lack of care during installation, splines have been damaged by the gear box main shaft.

Suggestion

• Replace the main shaft.

• Replace the clutch disc.

Solution

• Make sure that the splines properly match up.

• Lubricate with a proper quantity of grease.

____________________________________________

Failure on bearing

4.1 Clutch pedal binding

Cause

• The fork is out of shape.

• The release bearing guide tube is worn or the release arm I fork is bent I worn.

Suggestion

• Replace by a genuine release fork.

• Install new clutch and guide tube.

• Inspect all release bearing system components and repair or replace as Needed.

4.2 Release bearing damaged

Cause

• The fork is out of shape.

• The release bearing guide tube is worn or the release arm I fork is bent I worn.

Suggestion

• Replace by a genuine release fork.

• Install new clutch and guide tube.

• Inspect all release bearing system components and repair or replace as Needed.

4.2 Release bearing damaged

Cause

• Seal torn.

• Overheating during slippage.

• Leakage of the grease.

4.3 High pedal effort

Cause

• Seal torn.

• Overheating during slippage.

• Leakage of the grease.

4.3 High pedal effort

Cause

• The release bearing does not freely slide on the guide tube.

Suggestion

• Clean and lubricate the guide tube to bearing contact area with high temp grease.

• If the guide tube is worn or scored, replace the guide tube.

Cause

• The release bearing does not freely slide on the guide tube.

Suggestion

• Clean and lubricate the guide tube to bearing contact area with high temp grease.

• If the guide tube is worn or scored, replace the guide tube.

|

|